SELECT CATEGORIES

SELECT CATEGORIES

Universal Testing Machine – 20KN

YTS-20KN-102

Application Standards

ASTM E4, ASTM E8, ASTM E9, ASTM A370, ASTM D421, DIN 51221, ISO 7500-1, ISO 9513, EN 10002-2, EN 10002-4, EN 50081-1, 580081-1, 73/23/EEC, EN 61010-1, BS1610, BS 3846

Unmatched accuracy and versatile testing capabilities of the Universal testing machine

Unmatched accuracy and versatile testing capabilities of the Universal testing machine

Universal Testing Machine 20kN – The Ultimate Solution for Tensile and Compression Testing

The Universal Testing Machine 20kN is the pinnacle of material testing equipment to test any number of tensile, compression and bending tests. This universal testing machine UTM, has state-of-th

e-art testing systems that examine a variety of materials, leading to accurate testing results across every industry. Whether you require a tensile / compression tester, tensile (compression) tester, or tension machine, this 20kN model is your versatile universal machine, capable of all testing requirements.

Built for a maximum 20kN load; perfect for production testing, as an educational universal testing machine 20kN, or for structural testing. With automated testing, stable tensile stress and compliance with international testing standards, a universal testing machine is a versatile universal material testing machine that applies equally to professional material testing solutions.

Applications of the Universal Testing Machine – 20kN

Applications of the Universal Testing Machine – 20kN

Originally designed for civil engineering research, the 20kN Universal Testing Machine is recognized as a versatile approach tailored to fulfil the testing requirements for a wide variety of industries and materials. This universal testing machine is suited for routine testing or customized testing. Regardless, it has become an indispensable machine in quality assurance, research, development, and educational settings. Here’s how different industries take advantage of it:

Aerospace Industry

Aerospace Industry

The universal testing machine (20kN max) is important for testing Tensile strength and compression properties of metal alloys and composite materials for aircraft structures. Engineers use tensile stress-strain data to verify that the design will remain within a safe operating envelope under various load conditions. York Testing Solutions manufactures top-notch Universal testing machine (UTM) to satisfy clients and partners by all possible means.

Automotive Sector

Automotive Sector

The 20kN universal testing machine – tensile/compression tester – is used to ensure that critical automotive components such as suspension parts and safety structures meet the standards of safety. Tensile testing and compression tests are being used to determine materials’ tensile strength and durability under operational stresses. Our Universal Testing Machine (20kN) can provide you with reliable results in every sphere of your test.

Construction and Civil Engineering

Construction and Civil Engineering

This tensile (compression) tester is very important in the construction industry for compression testing and tensile testing of concrete, steel reinforcements, composite structures, etc. Compression moulding tests are done to verify the strength of building materials and the elasticity of the materials to withstand real conditions. At York Testing Solutions, you can get the ideal tensile tester with which you can easily perform all essential testing.

Polymers and Composites

Polymers and Composites

The set comprises of 20kN Universal Testing Machine that performs accurate tensile and compression properties for plastics, rubber and advanced composites. Material testing equipment, such as UTM, is essential to validate performance in consumer products, packaging and industrial components.

Universal Educational Testing Machine 20 kN

Universal Educational Testing Machine 20 kN

The Educational Universal Testing Machine 20 kN is to ensure that students and researchers learn tension/compression testing machines, tensile stress-strain behaviors that occur in the real world. It caters to labs and helps students understand the functionality of universal test machine and the testing standards.

Manufacturing and Production Testing

Manufacturing and Production Testing

The UTM 20kN Series universal tester is utilized in production for routine and acceptable tests for raw materials and end products. It ensures product quality by being able to part tensile tests, compression tests and verify tensile strength was completed to specification or international standard.

The Universal Testing machine is a 20kn computerized electromechanical universal testing machine to delivers efficient and reliable results. Besides it, the UTM 20KN computerized Universal Tensile Testing Machine ensures accuracy in all these application s.

Step-by-Step Guide on How the UTM Works

Step-by-Step Guide on How the UTM Works

Using the Universal Testing Machine 20kN is very simple due to the intuitive nature of the machine and powerful testing system. This guide will lead you to utilize its full potential.

Step 1: Prepare the Sample

Step 1: Prepare the Sample

Be sure to secure the test specimen in the grips of the universal testing equipment. If you’re carrying out tensile strength, compression properties, or tensile stress-strain, the initial set-up must be appropriately done to get accurate results.

Step 2: Set-Up Test Parameters

Step 2: Set-Up Test Parameters

Using the universal testing machine software, select which testing mode you wish to carry out (i.e. tensile test, compression test, or bending test). You will be prompted to input test parameters such as the maximum load (up to 20kN), speed (0.01 – 500 mm/min), tensile stress or compression stress.

Step 3: Choose the Testing Application

Step 3: Choose the Testing Application

Select between tensile and compression testing, compression molding test or routine testing – based on your testing requirements. The universal (tensile/compression) testing machine can run off-the-shelf tensile / compression tests between different modes in this area making it the perfect tensile / compression tester for diverse materials.

Step 4: Conduct Test

Step 4: Conduct Test

Once you push the start button, the test will begin. The 20kN Universal Testing machine will apply load while recording up to the second data in the testing fields – force, elongation, tensile, stress and strain simultaneously, using high-precision data sensors.

Step 5: Monitor and Analyze

Step 5: Monitor and Analyze

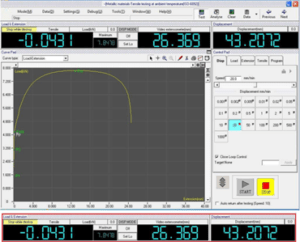

The computerized tensile testing machine displays real-time data and graphs for tensile stress-strain; compression stress; and Tensile Properties. This data is critical for testing of materials to confirm their performance against testing standards

Step 6: Record and Report Data

Step 6: Record and Report Data

After testing, the universal testing machine software pulls together the results into detailed reports. Further, it is exported for professional testing documentation,

These reports can be exported for professional testing, production testing, or structural testing evaluations.

Step 7: Routine Maintenance

Step 7: Routine Maintenance

Conduct a routine machine maintenance to ensure performance and durability. The 20kN Universal Testing Machine is built for stable tensile stress even when being pushed hard.

It dramatically improved the turnaround time of our lab’s testing. The 20 kN Universal Testing Machine is rigid, reliable, and it has been reproducible in tensile and compressed testing.

Materials Engineer, Aerospace

We have successfully conducted accurate tensile stress-strain analysis of polymers and composites with the 20 kN Universal Testing Machine (20kN max). A revolution for our R&D department!

R&D Manager, Automotive

Why Choose the 20kN Universal Testing Machine

Why Choose the 20kN Universal Testing Machine

20kN Universal Testing Machine – Tensile / Compression Tester engineered for accuracy and reliability that stands out among every testing machine. It is always preferred by laboratories, educational institutions and quality assurance organizations or departments.

20kn Universal Testing Machine – Tensile / Compression Tester:

20kn Universal Testing Machine – Tensile / Compression Tester:

Upholds tensile tests, compression tests, and tensile stress-strain to get an accurate analysis with universal testing machine software. With precision tensile stress and compression properties you can accomplish reliable tensile and compression testing by universal tensile testing machine.

Advanced Technology

Advanced Technology

Our UTM -20KN Computerized Tensile Testing Machine is fully equipped with modern software and high-resolution digital controls for easy data acquisition and real-time graph making. This computerised tensile testing machine will give you repeatable, traceable results in both tension and compression modes of 20kN.

Versatile Testing Capabilities

Versatile Testing Capabilities

The 20kN Universal Testing Machine – Tensile / Compression Tester is designed for a variety of applications. This universal test device operates on a variety of materials including metals, polymers, rubber, and composites perfect for routine testing. You can conduct Tension Testing or Analysis of Compressive Strength with unmatched accuracy. Ensure firm results by using 20kN computerized electromechanical universal testing machine systems.

Superior Build Quality

Superior Build Quality

Endorsed by testing equipment and testing solutions that satisfy testing applications in industries such as aerospace, automotive, and construction. Our Universal Material Testing Machine has a rigid frame, premium components made to last and minimize maintenance. Designed to accommodate a wide variety of grips and fixtures, it provides flexible and precise testing.

Accurate & Reliable Results

Accurate & Reliable Results

This materials testing machine works in static and dynamic testing modes. As a static testing machine, it is a robust static testing system that will allow the user to run long tests, without compromising the data, which is essential for quality assurance and R&D in materials testing machine.

Industry-Leading Support

Industry-Leading Support

When you purchase our 20kN Universal Testing Machine – Tensile / Compression Tester, you gain access to an entire team dedicated to helping you with installation, calibration, training and after-sales service. Our tensile testing machine provides you with leading support in each sphere of a test.

End-to-End Solutions

End-to-End Solutions

Whether you’re replacing your old machine or integrating testing automation, the 20kN Universal Testing Machine – Tensile / Compression Tester fits well into your process while ensuring full conformity with international testing standards. Here we also support state-of-the-art universal tensile testing machine maintenance protocols and testing section safety for secure operations.

Conclusion

Conclusion

The 20kN Universal Testing Machine, with its next-generation design, full commitment to testing systems, and advanced universal testing machines, is a critical piece of equipment for every industry that demands accuracy and reliability when evaluating material testing. This universal testing equipment allows you to efficiently test tensile strength, tensile stress-strain, and compression properties.

Contact us today to learn how we can help you utilize the 20kN Universal Testing Machine and a tensile machine to meet your testing requirements, and how we can take your testing process to the next level!

FAQs

FAQs

1.What materials can the 20kN Universal Testing Machine test?

1.What materials can the 20kN Universal Testing Machine test?

The 20kN UTM can test metals, plastics, rubber, composites, textiles, and more to fulfil various testing requirements by universal tensile testing machine.

2.How accurate is the 20kN Universal Testing Machine?

2.How accurate is the 20kN Universal Testing Machine?

The machine bestows an accurate result of ±0.5% of full scale, ensuring specific tensile and compression volume for a universal test.

3. Can the 20kN Universal Testing Machine be used for educational purposes?

3. Can the 20kN Universal Testing Machine be used for educational purposes?

Yes, the Educational Universal Testing Machine 20kN is developed for the manifestation of tensile and compression tests, making it ideal for training institutes and universities.

4. What are the key features of the 20kN Universal Testing Machine?

4. What are the key features of the 20kN Universal Testing Machine?

Features include updated universal testing machine software, automated testing, tensile/compression tester capabilities, routine testing and conformity with testing standards. Our universal tensile testing machine fulfils all the requirements of the test adequately.

5. What industries can benefit from using the 20kN Universal Testing Machine?

5. What industries can benefit from using the 20kN Universal Testing Machine?

A. it includes automotive, aerospace, construction, manufacturing, education, and professional testing labs that benefit from its diversity.

Extensometer

Extensometer

Available in Long extensometer and short extensometer.

Long Extensometer:

Long Extensometer:

The Long Extensometer is vital for assessing the stretchability of materials like rubber, plastic, PE, fabric, and webbing, especially those with elongation exceeding 20%. Typically, the testing specimen takes the form of a dumbbell, with the gauge length adjustable to suit its dimensions. Throughout the testing procedure, the extensometer adeptly detects any elongation automatically.

Specifications

Specifications

| Specifications | Standard | Extended |

| Test Stroke | 700mm | 1100mm |

| Extensometer Class | C2 | |

| Gauge Length | 15-100mm (Customizable) | |

| Operating Force | 0.25N Top of Form Bottom of Form | |

| Specimen Thickness | 0.10mm (Depending on the chosen jaw face) | |

| Arms Reach | 110mm | |

| Resolution | 0.0125mm | |

| Stroke resolution | 0.0001 mm | |

Short Extensometer:

Short Extensometer:

The Short Extensometer serves to evaluate the stiffness of materials like rigid plastic, metal, and those with an elongation below 50%. Sporting a refined displacement sensor and a sleek, compact design, it boasts a resolution of up to 0.5μm. Tailored specifications are available for instances where gauge length or elongation exceeds standard parameters. During tests with a maximum load under 20kN, the extensometer can remain affixed to the specimen until fracture occurs.

Specifications

Specifications

| Specifications | Short Extensometer |

| Gauge Length | 25mm/50mm |

| Resolution | 0.0005mm |

| Distance Clamp Rod’s Head | 78mm |

| Maximum Stroke | 25mm Top of Form Bottom of Form |

| Weight | 400g |

| Flat Specimen Thickness | 0-22mm |

| Round Specimen Diameter | Φ4.5-Φ21mm |

| Extensometer Class | C1 |

| Features | Using specialized fixtures to enhance clamping |

Software Operating Guidelines

Software Operating Guidelines

The YTS software reflects the collective expertise of leading testing machine manufacturers globally, incorporating insights and suggestions from end users. It merges the strengths of previous software versions with numerous new features. Its streamlined structure simplifies testing procedures, making them user-friendly, efficient, and dynamic. Within the main interface, users can access essential functions such as the computer software interface, data display, setup procedures, and sample size adjustment.

| Max Testing Force(KN) | 20 |

| Accuracy Class | Class 1/ Class 0.5 |

| Range of Force Measurement | Standard :2%~100%FS; Optional:0.4%~100%FS |

| Test Force Accuracy | within ±0.5% |

| Speed Precision | within ±0.5% set speed |

| Displacement Precision | within ±0.5% |

| Resolution Of Displacement | 0.001mm |

| Deformation Measurement Framework | Standard: Gauge length 50mm,Deformation range 10mm (can be customized) |

| Range of Deformation Measurement | 2%~100%FS |

| Deformation Measurement Precision | Within ±0.5% |

| Tensile Space(mm) | 700 (can be customized) |

| Compression Space(mm) | 700 (can be customized) |

| Test Width(mm) | Standard:360mm,400mm,520mm(customizable) |

| Beam Motion Distance | 1200mm |

| Dimension | Standard:350mm*670mm*1800mm |

| Weight | 300kg~500kg |

| Power Supply | AC220V,50Hz(customizable) |

| Optional | Various tensile compression bending test clamps can be configured according to user requirements. (can be customized) |

NOTE:

NOTE:

Related Products