Abrasion Tester-Rubber Hardness Abrasion Testing

Standards

DIN ISO 4649, NF ISO 4649, ASTM D 5963

ISO 4649 specifies two methods for the determination of the resistance of rubber to abrasion using a rotating cylindrical drum device.

Method A is for a non-rotating test piece, and method B is for a rotating test piece. Each method’s result can be reported as a relative volume loss or an abrasion resistance index.

Basic Equipment

A sample holder (rotating) with different loading weights, a rotating cylindrical roller, an emery sheet placed on the roller, and an electrical control.

Optional: An automatic vacuum cleaner connection and an optional heating module.

Range Of Application

An abrasion tester is used to determine the resistance of an elastomer to friction loss with a rotating or stationary test piece. The applications range from tires, conveyor belts, hoses, footwear, floor covering, etc.

Abrasion Testing is the process of measuring the amount of material worn away from a test item when rubbed against a certain grade of abrasive paper. To assess the ability of rubber materials, such as tires, conveyor belts, automobile belts, hoses, footwear, and several other goods, to withstand abrasion, it is necessary to subject them to testing in abrasive environments. The Abrasion Test Machine, specifically the rotary drum abrader, is an auxiliary testing equipment used to determine the wear resistance of rubber and the hardness of elastomers against abrasion. This process adheres to standardized rubber material testing methods, including ASTM D5963 standards, ISO 4649 testing, and DIN 53516 abrasion tests. These tests are crucial for conducting an elastomer durability test and evaluating friction loss in rubber, ensuring proper rubber quality control and product durability, as the real performance of rubber goods over their performance cycle is unpredictable without proper testing.

Applications

- Tire Industry: Assessing the abrasion resistance and durability of tires to ensure safety and longevity.

- Conveyor Belts: Testing the abrasion resistance of conveyor belts to minimize friction loss in rubber during operation.

- Automobile Belts and Hoses: Ensuring the durability and performance of rubber belts and hoses in vehicles through rigorous abrasion and hardness testing.

- Footwear: Evaluating the abrasion resistance of rubber soles to enhance product lifespan and customer satisfaction.

- Industrial Rubber Goods: Testing various rubber products to ensure they meet standardized rubber testing requirements for durability and performance.

By employing abrasion resistance testing equipment that adheres to ASTM D5963 standards, ISO 4649 testing, and DIN 53516 abrasion test methods, industries can ensure their rubber products’ high quality and reliability, enhancing overall product durability and performance.

| Dimensions of the test piece | Ø16 mm x 6 mm to Ø16 mm x 15 mm |

| Span length of the test piece | Maximum 13 mm |

| Clamping force of test piece (standard) | 2.5 N; 5.0 N; 7.5 N; 10.0 N |

| Abrasion path / rotations of the roller | 20 m / 42 R (rotations) – 40 m / 84 R |

| Speed of rotating test piece | 0.9 RPM |

| Speed of roller | 40 RPM |

| Feed | 4.2 mm/R |

| Peripheral speed | 0.32 m/s |

| Angle of inclination of sample holder | 3° |

| Roller diameter | 150 mm |

| Roller width | 460 mm |

Emery Sheet

| Dimensions | 472.5 (-0/+2) x 400.0 mm |

| Grain size | 60 |

Additional Weight 10 N

| Clamping force of test piece | 12.5 N; 15.0 N; 17.5 N; 20.0 N |

Abrasion Tester Standard Fe05000

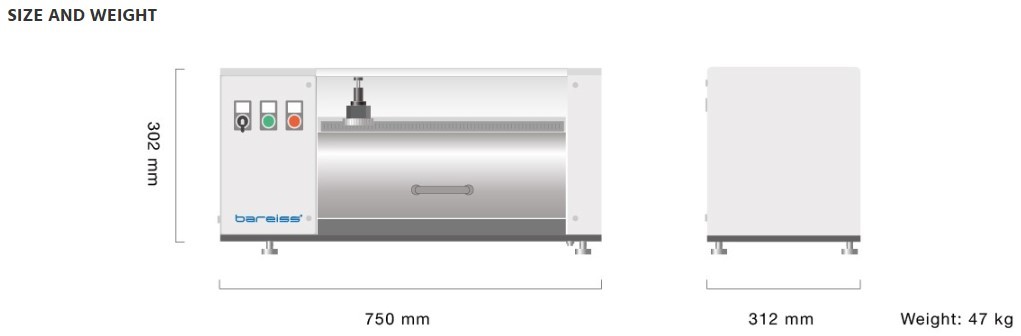

| Dimensions when packed (WxDxH) | 750 x 650 x 500 mm |

| Weight when packed | approx. 85 kg |

| Dimensions when unpacked (WxDxH) | 780 x 400 x 350 / 750 mm (closed / open) |

| Weight when unpacked | approx. 50 kg |

| Electrical connection data (operation) | 100 – 240 V 50 / 60 Hz 50 VA |

Abrasion Tester Automatic Vacuum Cleaner Connection Fe05000-01

| Dimensions when packed (WxDxH) | 750 x 650 x 500 mm |

| Weight when packed | approx. 85 kg |

| Dimensions when unpacked (WxDxH) | 780 x 400 x 350 / 750 mm (closed / open) |

| Weight when unpacked | approx. 50 kg |

| Electrical connection data (operation) | 100 – 240 V 50 / 60 Hz 50 VA + vacuum cleaner power |

| 100 – 240 V 50 / 60 Hz max. 10 A |

Abrasion Tester Heating Module Fe05000-02

| Dimensions when packed (WxDxH) | 750 x 650 x 500 mm 2100 VA heating operation |

| Weight when packed | approx. 90 kg |

| Dimensions when unpacked (WxDxH) | 780 x 600 x 350 / 750 mm (closed / open) |

| Weight when unpacked | approx. 55 kg |

| Electrical connection data (operation) | 100 – 240 V 50 / 60 Hz 2100 VA |

Operating Procedure: 1) Activate the abrasion tester by turning on the POWER rotary switch and opening the protective hood.

2) The test piece is securely attached to the sample holder and the protective hood is fully closed.

3) The ongoing automated standard abrasion procedure can be halted at any moment by clicking the STOP button.

4) Initiate the abrasion process by pressing the START button.

5) Once the designated route for abrasion is completed, the abrasion tester is automatically turned off, and the protective hood is opened.

6) The sample is removed from the sample holder, returned to its original place, and the protective hood is closed.

7) Turn off the abrasion tester using the POWER rotary switch after it has reached the activated lift, and then the measurement device will return to its original position. The optimal elevation is 2.0 mm.