Automatic Hardness Tester-IRHD Compact III

Standards

ISO 48-2| NF ISO 48| DIN 53512| ASTM D 1415| ASTM D792

ISO/17025 Accredited Calibration Certificate

Official ISO/17025 accredited calibration certificate is available for IRHD M & IRHD N

Basic Equipment

Electronic display, RS 232 Data transmitter, Interchangeable probe

Testing Methods

IRHD Micro, IRHD Normal

This affordable, adaptable semi-automatic hardness tester is capable of effortlessly examining materials such as O rings, seals, and tube-shaped elastomers. This automatic hardness tester is designed for soft elastomers with a thickness of up to 0.6mm, which can be conveniently examined using interchangeable measuring instruments for procedures IRHD M and IRHD N, yielding very accurate results. This hardness tester digital display ensures that measurements are easily readable, and the device adheres to international standards in terms of contact pressure and measurement time, ensuring hardness testing compliance with ASTM D1415, DIN ISO 48-2, and NF ISO 48 hardness standards.

The Hardness Tester IRHD Compact III is equipped with a digital hardness tester interface, capable of storing up to 300 test results, making it a hardness tester with memory that meets various operator needs. This indentation hardness tester is specifically designed for rubber hardness testing and plastic hardness measurement, ensuring accurate results across different materials. The interchangeable probes allow for flexibility in testing various elastomers, including the soft rubber hardness tester application. Additionally, the device supports micro IRHD testing and normal IRHD measurement, providing comprehensive data for elastomer testing. The optional “BareissOne” software is a highly beneficial, Windows-based program that provides functionalities such as data recording, article administration, graphical presentation of data and hardness curves, statistical assessment, and further analysis of the observed values. This enhances the functionality and usability of the hardness tester, making it a comprehensive tool for precise and efficient hardness testing.

| voltage | power supply set INPUT: 100 – 240 VAC; 50/60 Hz OUTPUT: 3,3 VDC |

| protection class | IP 50 |

| resolution | 0.1 IRHD |

| measuring range | IRHD M / IRHD N |

| measuring time | 1 – 99 s |

| data output | V24 RS 232 – 9600 Baud, 1 Start bit, 8 Data bits, 1 Stop bit |

| dimensions (LxWxH), weight | Test Stand : 200 x 250 x 570 mm, 9,0 kg Measuring Device IRHD M : 160 x 100 x 140 mm, 1,4 kg Measuring Device IRHD N : 70 x 90 x 150 mm, 1,9 kg Pick-up bracket IRHD N : 100 x 100 x 150 mm, 1,3 kg |

| Test Method | Total Force(mN) | Force on foot(mN) | Indenter ball Ø (mm) | Measuring distance (mm) | Range of reading |

| IRHD M | 153.3mN | 235mN | 0.4 mm | 0.3 | 30-100 |

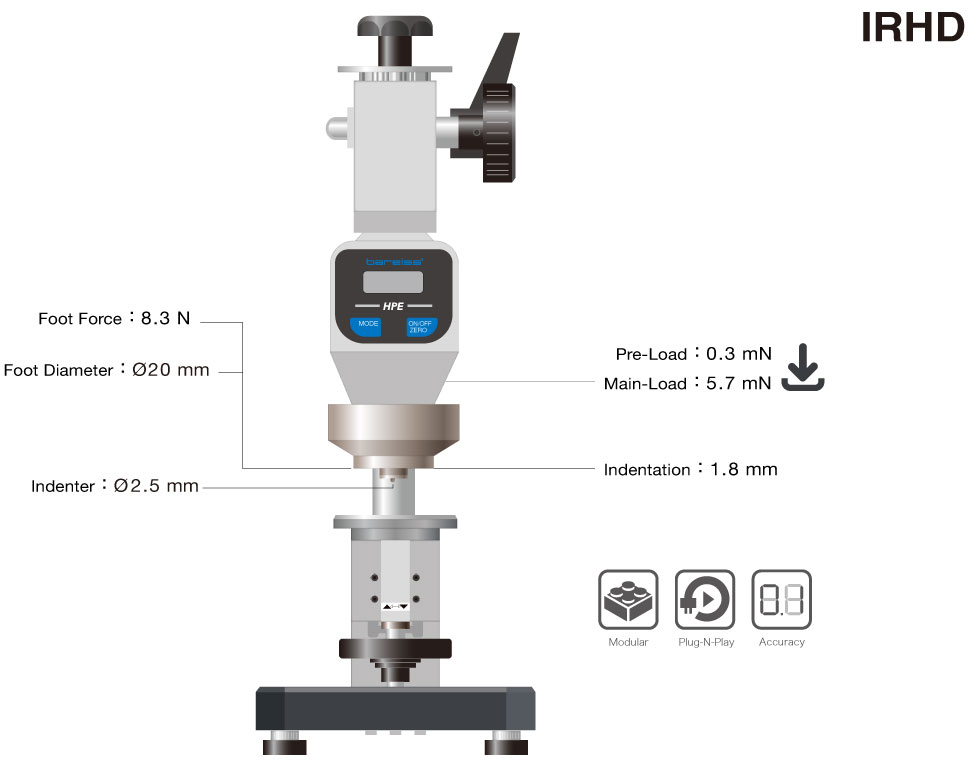

| IRHD N | 5.7N | 8.3N | 2.5 mm | 1.8 | 30-100 |

Application

| Test Method | Range of Application | Norms | Minimum Material Thickness [mm] |

| IRHD M | hoses, tubes O-rings, moulded parts, norm plates and seals | DIN ISO 48, ASTM D 1415, NFT 46-003, BS903 Part. A 26 |

0,6 |

| IRHD N | soft rubber, high elastic materials, plastic ductile materials | DIN ISO 48, ASTM D 1415, NFT 46-003, BS903 Part. A 26 |

6 |

Test method: IRHD M

Test method: IRHD N

1) The equipment comprises an electronic display with a resolution of up to 0.1 IRHD.

2) Data transfer can be achieved via an RS-232 interface.

3) The probes can be easily switched between micro and regular sizes, depending on the substance being tested.

The IRHD Compact III hardness tester is a semi-automatic device used for testing hardness. It is known for its cost-effectiveness.

5) Special fixtures can be used to test O rings, seals, and tube-shaped samples by attaching them to the instrument.

6) The embedded memory is used for storing a maximum of 300 test results, together with optical and audio data, while conducting measurements.