Rebound Resilience Tester – Rubber Tester

Standards

ASTM D7121, DIN 53512, ISO 4662, ASTM D 1054

DAkkS Calibration Certificate

Official DAkkS calibration certificate according to DIN EN ISO/IEC 17025

Basic Equipment

Guided pendulum hammer, External electronic unit, and optional temperature control module

Presenting the Rebound Resilience Tester, an unparalleled tool for rubber quality control and quantifying the pliability of elastomers and other substances. This high-precision resilience tester uses advanced push pendulum technology to guarantee precise and dependable outcomes unaffected by operator bias. This device ensures high-quality and reliable testing results and is compliant with the ASTM D1054 standard, ISO 4662, and DIN 53512 resilience test requirements. The rubber impact resilience measurement capabilities of this tester allow for comprehensive material elasticity assessment, including detailed shock absorption tests essential for industrial rubber testing. In addition, the laboratory resilience tester can conduct pendulum resilience measurements on heated test specimens at temperatures of up to 100° C when equipped with the optional temperature control module. This feature enables the identification of variations in dynamic rubber behavior under varying temperature settings, offering crucial insights for your research and development endeavors. Elevate your automated rubber testing skills with the Rebound Resilience Tester.

Applications

The Rebound Resilience Tester is essential for various applications, including:

- Material Research and Development: It is crucial to develop new materials by identifying variations in material elasticity under different temperature settings.

- Quality Control: Ensuring the consistent performance of rubber and elastomer products by measuring their impact resilience and shock absorption capabilities.

- Automotive Industry: Testing the elasticity and resilience of vehicle rubber components to ensure durability and performance.

- Footwear Industry: Measuring the shock absorption properties of shoe soles and other elastomeric components.

- Aerospace and Defense: Assessing the resilience and impact resistance of materials used in critical applications.

- Sports Equipment Manufacturing: Testing various sports gear’s elasticity and shock absorption properties to ensure safety and performance.

By utilizing the Rebound Resilience Tester, industries can achieve precise and reliable measurements of rubber elasticity and resilience, ensuring their products meet the highest standards of performance and durability.

| Voltage | INPUT: 100 – 240 VAC; 50/60 Hz OUTPUT: 3,3 VDC |

| Resolution | 0.1 % |

| Test method | Resilience Elasticity test |

| Interface RS 232 | 9600 Baud, 1 Start bit, 8 Data bits, 1 Stop bit |

| Capacity | 0,5 J und 0,2 J |

| Pendulum length | 200 mm |

| Drop angle of the pendulum | 90° |

| Impact speed | 2 m/s |

| Range of specimen thickness | 0 – 60 mm |

| Scale value | 1 mm |

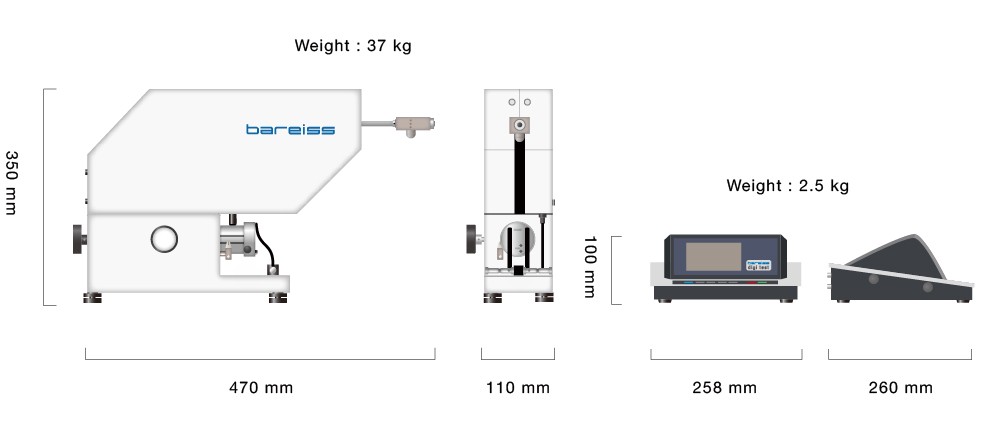

| Dimensions (LxWxH) / weight | Rebound device: 200 x 250 x 570 mm / 33 kgs Electronic unit: 290 x 260 x 120 mm / 2 kgs |

Pendulum hammer 0,5 J-hammer edge-hemisphere of Ø 15 mm

| Pendulum Hammer | Range of Application | Standards | Specimen |

|---|---|---|---|

| Pendulum hammer 0,5 J hammer edge, hemisphere Ø 15 mm |

Elastomers 30 up to 85 Shore A |

ASTM D7121, DIN 53512, ISO 4662, ASTM D 1054 |

Thickness: 12.5 ± 0.5 mm Diameter: 29-53 mm |

Pendulum hammer 0,2 J-hammer edge-hemisphere of Ø 30 mm (Optional)

| Pendulum Hammer | Range of Application | Standards | Specimen |

|---|---|---|---|

| Pendulum hammer 0,2 J hammer edge, hemisphere Ø 30 mm |

Soft elastic foams | DIN 53573 Shape A |

Thickness: 50 ± 2 mm Square lateral length: 80*80 mm |

Pendulum hammer 0,2J cyl. Ø40mm with spherical cone r=40mm (Optional)

| Pendulum Hammer | Range of Application | Standards | Specimen |

|---|---|---|---|

| Pendulum hammer 0,2 J hammer edge, Cylinder Ø 40 mm with spherical cone r= 40mm |

Soft elastic foams | DIN 53573 Shape B |

Thickness: 50 ± 2 mm Square lateral length: 80*80 mm |

Our rebound resilience tester has a variety of characteristics that establish it as the preferred option for dependable and precise testing.

1) By using our optional temperature control module, you may effortlessly conduct measurements under diverse temperature situations, therefore acquiring crucial insights into the behavior of materials. The accuracy and consistency of our guided pendulum movement are guaranteed with a self-checking mechanism that monitors the swinging time of the pendulum hammer.

2) Our versatile spring clamp system enables effortless clamping of diverse specimen samples with a maximum thickness of 50mm, optimizing your testing procedure. Access your findings effortlessly utilizing our external electrical device equipped with a backlit screen.

The Rebound Resilience Tester is equipped with an automated test sequence that can identify samples for idling and damage to the anvil plate. Additionally, our optional clamping mechanism offers the ease of applying a consistent force of 200N to securely fasten your test specimen.

Discover unparalleled testing possibilities with the Rebound Resilience Tester.

The operating procedure for the Rebound Resilience Tester prioritizes user-friendly design, enabling users to conduct dependable and precise measurements via a straightforward process.

1) Activate the electronic device and choose the required measurement configuration based on established standards. The equipment exhibits Mode 1 in accordance with established criteria, and you may verify this by clicking the Ok button on the electronic unit.

2) The measurement is initiated, and our controlled pendulum motion causes the pendulum to descend six times from the horizontal position to the same location on the specimen. Subsequently, the pendulum is arrested or halted, therefore repeating the impact method to assess the durability of your material.

3) To achieve more accuracy, our tester applies three mechanical pre-conditioning impacts prior to measuring and presenting the resilience for the fourth, fifth, and sixth impacts. To enhance precision, the median value is then computed.

4) Require to conduct measurements within precise temperature parameters? The optional tempering module enables measurements at temperatures up to 100°C, while simultaneously conducting mechanical preconditioning to ensure dependable results.

5) Additionally, our electronic device offers enhanced versatility by including a control feature for measuring friction control. Merely observe the recorded value on the screen and await an auditory notification indicating the completion of the monitoring process. Record the frequency of oscillations and the duration to assess the efficacy of the control.

Discover unparalleled testing capabilities with the Rebound Resilience Tester – the preferred option for precise and dependable measures of material elasticity.