SELECT CATEGORIES

SELECT CATEGORIES

Universal Testing Machine – 20KN

YTS-20KN-102

Application Standards

ASTM E4, ASTM E8, ASTM E9, ASTM A370, ASTM D421, DIN 51221, ISO 7500-1, ISO 9513, EN 10002-2, EN 10002-4, EN 50081-1, 580081-1, 73/23/EEC, EN 61010-1, BS1610, BS 3846

Applications

The YTS-20KN-102 is meticulously crafted in accordance with ASTM, ISO, DIN, and other esteemed standards. This computer-controlled precision testing apparatus is adept at conducting tension, compression, bending, and shearing tests across a broad spectrum of materials. Renowned for its exceptional stability and precision, it comes equipped with a PC system and printer for displaying graphs and test results, executing programmed tests, and facilitating data processing and printing. Additionally, it includes modulus features tailored for testing metals, springs, textiles, rubber, plastics, foils, films, foams, timber, wires, adhesives, and various other materials, including creep tests. Its versatility finds applications across diverse sectors, ranging from industrial manufacturing facilities to mineral enterprises and educational institutions, including high schools.

Mechanical Attributes

- Load Frame

The load frames of YTS-20KN-102 are meticulously designed with human factors in mind, prioritizing safety, minimizing operator fatigue, and maximizing flexibility. These frames support various testing configurations, including the Compression Testing Machine for compression-based assessments, as well as the UTM for Metal Testing, UTM for textile testing, and UTM for packaging testing, ensuring the system is versatile across multiple industries. To ensure proper gripping of materials during tensile tests, tensile grips are used, while adherence to standards such as ASTM A370 for UTM and ASTM D421 for UTM guarantees compliance with industry norms. Across all frame designs, we integrate exceptionally robust crosshead guidance to achieve the highest level of lateral stiffness, ensuring precise and reliable performance.

- High Accuracy

Experience exceptional accuracy with our preloaded precision ball-screw system, engineered for high speed, low noise operation. Enjoy precise speed and position measurements with minimal noise interference, guaranteeing accurate testing results.

- Improved Stiffness Frame

Equipped with a four-column configuration and heavy-duty pre-loaded bearings, our load frames are engineered for unparalleled stiffness. Advanced features such as preloaded ball screws, precision guidance columns, and a symmetrical drive system further enhance frame stiffness and alignment, ensuring optimal performance in every test.

Safety Attributes

Rest assured with automatic safety features of YTS-20KN-102 that halt testing operations when a significant change in test force surpasses predefined limits. Prioritizing operator safety, these features provide added peace of mind during testing procedures.

Over-Travel Limits

Dual over-travel limits, conveniently located on the front console, offer proactive protection against crosshead overshooting and sensor overloads. Customize these limits to specific distances using the graduated rule along the column, ensuring precise control over testing parameters.

Test Controller Attributes

- Versatile Closed Loop Control

The test controller of YTS-20KN-102 offers three closed-loop control modes for force, deformation, and displacement. Each control ring can seamlessly switch between modes without causing any disruption, ensuring smooth transitions during testing.

- High-Precision Data Acquisition

Incorporating up to three channels of 24-bit high-precision analog-to-digital converters (A/D converters), the test controller ensures accurate and reliable data acquisition.

- Flexible Output Options

The digital output interface is capable of generating pulse signals ranging from 0 to 2MHz, while the analog output interface can deliver 16-bit precision voltage signals ranging from -10V to +10V. These outputs enable precise control of servo motors, servo valves, and other actuators.

- Enhanced Connectivity via USB

Supporting USB interface mode, the test controller significantly increases data transmission rates to accommodate higher sampling frequencies, enhancing overall performance.

- Sensor Recognition and Memory Function

Featuring a sensor self-recognition system and correction parameter memory function, the test controller facilitates quick replacement of various sensors while maintaining accuracy and consistency in measurements.

- User-Friendly Interface

Equipped with an LCD display hand control box, the test controller boasts a sleek appearance and intuitive operation, enhancing user experience during testing procedures.

- Comprehensive Safety Features

The test controller of YTS-20KN-102 comes equipped with limit, overload protection, emergency stop, and other safety features, ensuring the safety of both equipment and operators during testing operations.

| Max Testing Force(KN) | 20 |

| Accuracy Class | Class 1/ Class 0.5 |

| Range of Force Measurement | Standard :2%~100%FS; Optional:0.4%~100%FS |

| Test Force Accuracy | within ±0.5% |

| Speed Precision | within ±0.5% set speed |

| Displacement Precision | within ±0.5% |

| Resolution Of Displacement | 0.001mm |

| Deformation Measurement Framework | Standard: Gauge length 50mm,Deformation range 10mm (can be customized) |

| Range of Deformation Measurement | 2%~100%FS |

| Deformation Measurement Precision | Within ±0.5% |

| Tensile Space(mm) | 700 (can be customized) |

| Compression Space(mm) | 700 (can be customized) |

| Test Width(mm) | Standard:360mm,400mm,520mm(customizable) |

| Beam Motion Distance | 1200mm |

| Dimension | Standard:350mm*670mm*1800mm |

| Weight | 300kg~500kg |

| Power Supply | AC220V,50Hz(customizable) |

| Optional | Various tensile compression bending test clamps can be configured according to user requirements. (can be customized) |

Note:

*Extra wide and/or extra height frames are available.

*Power supply system is completely customizable.

*Tensile space, test width, and speed is completely customizable.

- Comprehensive Digital Control

The entire measurement and control system utilizes a specialized controller, enabling digital adjustments of zero point, load, deformation, and displacement. Operating this system is straightforward, ensuring high reliability and ease of use.

- Versatile Parameter Storage and Management

Capable of storing, setting, and loading various parameters, facilitating the connection of multiple transducers to a single load frame. This feature enhances convenience and flexibility in testing setups.

- Closed-Loop Control with Visual Feedback

Implements closed-loop control while displaying reference curves during operator adjustments. Users can observe the effects of parameter changes on the closed-loop system in real-time, enhancing control precision.

- Advanced Graphic Functions

Offers comprehensive graphic capabilities for curve manipulation, including reproduction, magnification, reduction, self-adaptation, overlaying, and displaying/printing curves within specified ranges. Users can also pinpoint test point coordinates for detailed analysis.

- Efficient Data Processing

Supports automatic analysis and graphic user-machine interaction for streamlined data checking and comparison of test results, ensuring efficiency in data management.

- Multi-level User Identity Management

Implements multi-level user identity management, granting different functionalities to each user level. This approach not only enhances operational efficiency for ordinary operators but also provides effective system protection.

- Database-Based Data Storage

Test data is stored in text file format within a database, facilitating user inquiries and enabling utilization of various commercial report forms for data reprocessing. Additionally, data transfer to the internet is made convenient.

- Multi-Channel Control Capability

Offers control over multiple parameters such as displacement, force, deformation, stress, strain, constant stress, and constant strain, providing versatility and adaptability for diverse testing needs.

Extensometer

Available in Long extensometer and short extensometer.

Long Extensometer:

The Long Extensometer is vital for assessing the stretchability of materials like rubber, plastic, PE, fabric, and webbing, especially those with elongation exceeding 20%. Typically, the testing specimen takes the form of a dumbbell, with the gauge length adjustable to suit its dimensions. Throughout the testing procedure, the extensometer adeptly detects any elongation automatically.

Specifications

| Specifications | Standard | Extended |

| Test Stroke | 700mm | 1100mm |

| Extensometer Class | C2 | |

| Gauge Length | 15-100mm (Customizable) | |

| Operating Force | 0.25N Top of Form Bottom of Form | |

| Specimen Thickness | 0.10mm (Depending on the chosen jaw face) | |

| Arms Reach | 110mm | |

| Resolution | 0.0125mm | |

| Stroke resolution | 0.0001 mm | |

Short Extensometer:

The Short Extensometer serves to evaluate the stiffness of materials like rigid plastic, metal, and those with an elongation below 50%. Sporting a refined displacement sensor and a sleek, compact design, it boasts a resolution of up to 0.5μm. Tailored specifications are available for instances where gauge length or elongation exceeds standard parameters. During tests with a maximum load under 20kN, the extensometer can remain affixed to the specimen until fracture occurs.

Specifications

| Specifications | Short Extensometer |

| Gauge Length | 25mm/50mm |

| Resolution | 0.0005mm |

| Distance Clamp Rod’s Head | 78mm |

| Maximum Stroke | 25mm Top of Form Bottom of Form |

| Weight | 400g |

| Flat Specimen Thickness | 0-22mm |

| Round Specimen Diameter | Φ4.5-Φ21mm |

| Extensometer Class | C1 |

| Features | Using specialized fixtures to enhance clamping |

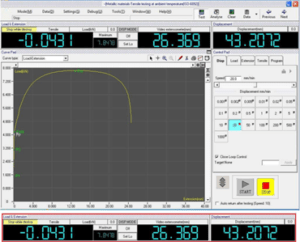

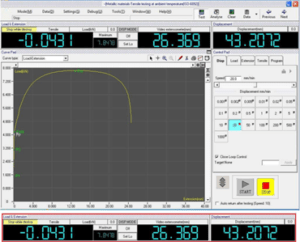

Software Operating Guidelines

The YTS software reflects the collective expertise of leading testing machine manufacturers globally, incorporating insights and suggestions from end users. It merges the strengths of previous software versions with numerous new features. Its streamlined structure simplifies testing procedures, making them user-friendly, efficient, and dynamic. Within the main interface, users can access essential functions such as the computer software interface, data display, setup procedures, and sample size adjustment

.

Universal Testing Machine – 20KN

YTS-20KN-102

Application Standards

ASTM E4, ASTM E8, ASTM E9, ASTM A370, ASTM D421, DIN 51221, ISO 7500-1, ISO 9513, EN 10002-2, EN 10002-4, EN 50081-1, 580081-1, 73/23/EEC, EN 61010-1, BS1610, BS 3846

Description

Applications

The YTS-20KN-102 is meticulously crafted in accordance with ASTM, ISO, DIN, and other esteemed standards. This computer-controlled precision testing apparatus is adept at conducting tension, compression, bending, and shearing tests across a broad spectrum of materials. Renowned for its exceptional stability and precision, it comes equipped with a PC system and printer for displaying graphs and test results, executing programmed tests, and facilitating data processing and printing. Additionally, it includes modulus features tailored for testing metals, springs, textiles, rubber, plastics, foils, films, foams, timber, wires, adhesives, and various other materials, including creep tests. Its versatility finds applications across diverse sectors, ranging from industrial manufacturing facilities to mineral enterprises and educational institutions, including high schools.

Mechanical Attributes

- Load Frame

The load frames of YTS-20KN-102 are meticulously designed with human factors in mind, prioritizing safety, minimizing operator fatigue, and maximizing flexibility. These frames support various testing configurations, including the Compression Testing Machine for compression-based assessments, as well as the UTM for Metal Testing, UTM for textile testing, and UTM for packaging testing, ensuring the system is versatile across multiple industries. To ensure proper gripping of materials during tensile tests, tensile grips are used, while adherence to standards such as ASTM A370 for UTM and ASTM D421 for UTM guarantees compliance with industry norms. Across all frame designs, we integrate exceptionally robust crosshead guidance to achieve the highest level of lateral stiffness, ensuring precise and reliable performance.

- High Accuracy

Experience exceptional accuracy with our preloaded precision ball-screw system, engineered for high speed, low noise operation. Enjoy precise speed and position measurements with minimal noise interference, guaranteeing accurate testing results.

- Improved Stiffness Frame

Equipped with a four-column configuration and heavy-duty pre-loaded bearings, our load frames are engineered for unparalleled stiffness. Advanced features such as preloaded ball screws, precision guidance columns, and a symmetrical drive system further enhance frame stiffness and alignment, ensuring optimal performance in every test.

Safety Attributes

Rest assured with automatic safety features of YTS-20KN-102 that halt testing operations when a significant change in test force surpasses predefined limits. Prioritizing operator safety, these features provide added peace of mind during testing procedures.

Over-Travel Limits

Dual over-travel limits, conveniently located on the front console, offer proactive protection against crosshead overshooting and sensor overloads. Customize these limits to specific distances using the graduated rule along the column, ensuring precise control over testing parameters.

Test Controller Attributes

- Versatile Closed Loop Control

The test controller of YTS-20KN-102 offers three closed-loop control modes for force, deformation, and displacement. Each control ring can seamlessly switch between modes without causing any disruption, ensuring smooth transitions during testing.

- High-Precision Data Acquisition

Incorporating up to three channels of 24-bit high-precision analog-to-digital converters (A/D converters), the test controller ensures accurate and reliable data acquisition.

- Flexible Output Options

The digital output interface is capable of generating pulse signals ranging from 0 to 2MHz, while the analog output interface can deliver 16-bit precision voltage signals ranging from -10V to +10V. These outputs enable precise control of servo motors, servo valves, and other actuators.

- Enhanced Connectivity via USB

Supporting USB interface mode, the test controller significantly increases data transmission rates to accommodate higher sampling frequencies, enhancing overall performance.

- Sensor Recognition and Memory Function

Featuring a sensor self-recognition system and correction parameter memory function, the test controller facilitates quick replacement of various sensors while maintaining accuracy and consistency in measurements.

- User-Friendly Interface

Equipped with an LCD display hand control box, the test controller boasts a sleek appearance and intuitive operation, enhancing user experience during testing procedures.

- Comprehensive Safety Features

The test controller of YTS-20KN-102 comes equipped with limit, overload protection, emergency stop, and other safety features, ensuring the safety of both equipment and operators during testing operations.

Technical Specification

- Max Testing Force: 20KN

- Accuracy Class: Class 1 / Class 0.5

- Force Measurement Range: Standard: 2%~100%FS; Optional: 0.4%~100%FS

- Test Force Accuracy: Within ±0.5%

- Speed Precision: Within ±0.5% of set speed

- Displacement Precision: Within ±0.5%

- Resolution of Displacement: 0.001mm

- Deformation Measurement Framework: Standard: 50mm gauge length, 10mm deformation range (customizable)

- Deformation Measurement Range: 2%~100%FS

- Deformation Measurement Precision: Within ±0.5%

- Tensile Space: 700mm (customizable)

- Compression Space: 700mm (customizable)

- Test Width: Standard: 360mm, 400mm, 520mm (customizable)

- Beam Motion Distance: 1200mm

- Dimensions: Standard: 350mm × 670mm × 1800mm

- Weight: 300kg~500kg

- Power Supply: AC220V, 50Hz (customizable)

- Optional Features: Various clamps for tensile, compression, and bending tests (customizable)

Key Features

- Comprehensive Digital Control

The entire measurement and control system utilizes a specialized controller, enabling digital adjustments of zero point, load, deformation, and displacement. Operating this system is straightforward, ensuring high reliability and ease of use.

- Versatile Parameter Storage and Management

Capable of storing, setting, and loading various parameters, facilitating the connection of multiple transducers to a single load frame. This feature enhances convenience and flexibility in testing setups.

- Closed-Loop Control with Visual Feedback

Implements closed-loop control while displaying reference curves during operator adjustments. Users can observe the effects of parameter changes on the closed-loop system in real-time, enhancing control precision.

- Advanced Graphic Functions

Offers comprehensive graphic capabilities for curve manipulation, including reproduction, magnification, reduction, self-adaptation, overlaying, and displaying/printing curves within specified ranges. Users can also pinpoint test point coordinates for detailed analysis.

- Efficient Data Processing

Supports automatic analysis and graphic user-machine interaction for streamlined data checking and comparison of test results, ensuring efficiency in data management.

- Multi-level User Identity Management

Implements multi-level user identity management, granting different functionalities to each user level. This approach not only enhances operational efficiency for ordinary operators but also provides effective system protection.

- Database-Based Data Storage

Test data is stored in text file format within a database, facilitating user inquiries and enabling utilization of various commercial report forms for data reprocessing. Additionally, data transfer to the internet is made convenient.

- Multi-Channel Control Capability

Offers control over multiple parameters such as displacement, force, deformation, stress, strain, constant stress, and constant strain, providing versatility and adaptability for diverse testing needs.

Accessories

Extensometer

Available in Long extensometer and short extensometer.

Long Extensometer:

The Long Extensometer is vital for assessing the stretchability of materials like rubber, plastic, PE, fabric, and webbing, especially those with elongation exceeding 20%. Typically, the testing specimen takes the form of a dumbbell, with the gauge length adjustable to suit its dimensions. Throughout the testing procedure, the extensometer adeptly detects any elongation automatically.

Specifications

Specifications | Standard |

Test Stroke | 700mm |

Extensometer Class | C2 |

Gauge Length | 15-100mm (Customizable) |

Operating Force | 0.25N

Top of Form Bottom of Form |

Specimen Thickness | 0.10mm (Depending on the chosen jaw face) |

Arms Reach | 110mm |

Resolution | 0.0125mm |

Stroke resolution | 0.0001 mm |

Extended | 1100mm |

Short Extensometer:

The Short Extensometer serves to evaluate the stiffness of materials like rigid plastic, metal, and those with an elongation below 50%. Sporting a refined displacement sensor and a sleek, compact design, it boasts a resolution of up to 0.5μm. Tailored specifications are available for instances where gauge length or elongation exceeds standard parameters. During tests with a maximum load under 20kN, the extensometer can remain affixed to the specimen until fracture occurs.

Specifications

| Specifications | Short Extensometer |

| Gauge Length | 25mm/50mm |

| Resolution | 0.0005mm |

| Distance Clamp Rod’s Head | 78mm |

| Maximum Stroke | 25mm Top of Form Bottom of Form |

| Weight | 400g |

| Flat Specimen Thickness | 0-22mm |

| Round Specimen Diameter | Φ4.5-Φ21mm |

| Extensometer Class | C1 |

| Features | Using specialized fixtures to enhance clamping |

Software Operating Guidelines

The YTS software reflects the collective expertise of leading testing machine manufacturers globally, incorporating insights and suggestions from end users. It merges the strengths of previous software versions with numerous new features. Its streamlined structure simplifies testing procedures, making them user-friendly, efficient, and dynamic. Within the main interface, users can access essential functions such as the computer software interface, data display, setup procedures, and sample size adjustment

.