SELECT CATEGORIES

SELECT CATEGORIES

Universal Testing Machine – 5KN

YTS-5KN-101

Application Standards

ASTM E4, ASTM E83, DIN 51221, ISO 7500-1, ISO 9513, EN 10002-2, EN 10002-4, EN 50081-1, 580081-1, 73/23/EEC, EN 61010-1, BS1610, BS 3846

Universal Testing Machine 5KN – Precision Testing for Material Science & Industry

Contact us for demo

Product Overview

Product Overview

The Universal Testing Machine 5KN is a universal testing machine that is both versatile and accurate used for tensile testing, compression testing, and general materials testing in any industry. With its high-capacity 5KN load, the universal testing machine (UTM) provides accurate measurements of mechanical properties, and it is a crucial quality control equipment, research and development equipment.

With the new test software, the machine has simple data collection and analysis, which improves the testing process. With the availability of various materials, the machine provides secure test results and supports the unique requirements of varied applications.

Key Features of the Universal Testing Machine 5KN

Key Features of the Universal Testing Machine 5KN

5KN Load Capacity for Accurate Tensile Testing and Compression Testing

5KN Load Capacity for Accurate Tensile Testing and Compression Testing

Tensile Tester (5KN) for Precise Tensile Stress Measurement

Tensile Tester (5KN) for Precise Tensile Stress Measurement

Testing Software for Easy Data Analysis and Reporting

Testing Software for Easy Data Analysis and Reporting

Testing Software for Easy Data Analysis and Reporting

Testing Software for Easy Data Analysis and Reporting

How the Universal Testing Machine 5KN Works

How the Universal Testing Machine 5KN Works

Step-by-Step Tensile Testing Procedure

Step-by-Step Tensile Testing Procedure

1. Specimen Mounting and Preparation

1. Specimen Mounting and Preparation

2. Choosing Test Parameters

2. Choosing Test Parameters

3. Starting the Test

3. Starting the Test

4. Real-Time Data Acquisition

4. Real-Time Data Acquisition

5. Post-Test Analysis and Reporting

5. Post-Test Analysis and Reporting

It dramatically improved the turnaround time of our lab’s testing. The 20 kN Universal Testing Machine is rigid, reliable, and it has been reproducible in tensile and compressed testing.

Materials Engineer, Aerospace

We have successfully conducted accurate tensile stress-strain analysis of polymers and composites with the 20 kN Universal Testing Machine (20kN max). A revolution for our R&D department!

R&D Manager, Automotive

Real-Time Compression Force Measurement and Analysis

Real-Time Compression Force Measurement and Analysis

In compression testing, the universal testing machine 5KN captures the material’s response to compressive stress in terms of tracking deformation, peak force, yield points, and material failure, if any. The high sampling rate ensures the capture of even slight changes in force or displacement. For compression testing, the same universal tester is set up with platens or compression fixtures. The sample (e.g., foam cube, concrete test sample, or polymer block) is positioned between platens, and the crosshead descends, making a compression load in universal testing machines.

This double functionality renders the 5KN machine a real universal materials testing machine, well suited to be used in materials and components testing in industries where both tensile and compression tests are necessary. Thus, automated tensile testing can make your process fast and easy with universal testers

This double functionality renders the 5KN machine a real universal materials testing machine, well suited to be used in materials and components testing in industries where both tensile and compression tests are necessary in universal testing machines.

Benefits of Using the Universal Testing Machine 5kN

Benefits of Using the Universal Testing Machine 5kN

The 5kN Universal Testing Machine is a vital tool for reliable and accurate material analysis in laboratories or production surroundings. Whether you’re testing textiles, polymers, metals or composites, this dual column testing machine presents reliability for tensile and compression test applications.

Below are the key benefits of our universal tensile testing machine, including how it provides a high-quality and perfect workflow:

High Precision in Tensile & Compression Applications

High Precision in Tensile & Compression Applications

Our UTM testing machines are precisely constructed to provide consistent, accurate test results for tensile testing applications and compression test setups. Whatever the test may be, whether it is a tensile test, tension test, or tear testing method, the universal tester will provide consistent measures and metrics for each of the test methods.

Numerous Testing Capabilities

Numerous Testing Capabilities

The 5kN UTM provides a supporter of many material types and types of tests, such as tensile testers, compression platens and multipurpose grips for creating versatile applications, ranging from an effective test of material to complete tensile testing solutions and beyond for many different industries. The specific configuration may be used for load UTM machine operations and also with other standard testing equipment.

Engineered for Accuracy & Repeatability

Engineered for Accuracy & Repeatability

Our UTM machine utilizes a high-resolution load cell providing accurate values of both tensile force and elongation. Therefore, as a member of the modern UTM machine family, it guarantees that the tensile testing machines have the lowest degree of error, making it ideal for stringent sets of tensile testing systems and certified lab testing procedures.

Perfect for Small Labs and High-Throughput Labs

Perfect for Small Labs and High-Throughput Labs

Our 5kN universal testing machine is compact and fits easily in small labs, yet still retains the features of larger united testing machines. It’s optimized to run fast and reliable operations as tensile testers, giving you high throughput and minimal downtime.

Treatment Software

Treatment Software

The UTM machine testing platform is outfitted with effective software for the seamless real-time control of data capture and monitoring, including easy configuration of testing parameters and automatic generation of results. This is critical for businesses that perform repeated tensile tests or companies performing multiple variants of tests in UTM machine test environments.

Wide Material Compatibility

Wide Material Compatibility

It doesn’t matter if testing polymers or composites, all of our material testing machine are set up to perform various tensile testing machines. Your material can be a universal compression testing machine, or a tension machine for one of the widest universal testing machines range.

In Good Company

In Good Company

Our universal testers are embraced by laboratories and manufacturers worldwide. This model is part of our universal testing machines (UTMs) family, and like the united testing UTM systems we build as a unit, it embodies the promise of excellence.

Affordable and Expandable

Affordable and Expandable

If you’re looking for affordable testing solutions without breaking the bank, the 5kN model is a great introduction to the world of affordable professional testing. Its testing capacity has been tailored for light to medium materials while maintaining a high level of accuracy and dependability. This universal testing model is flexible and can switch between different material testing machines for your expanding testing needs.

Worldwide Compliance

Worldwide Compliance

With fully integrated UTM testing machines, complete with industry-accepted UTM fixtures, there is no question that our material testing machine complies with international testing requirements. It’s perfect for manufacturers who need global certification and testing systems.

Machine with Many Possibilities

Machine with Many Possibilities

This unit provides a reliable and consistent platform to conduct all sorts of material testing machine applications or universal testing machine for plastics and metals applications. Contrary to other material testing machines, with the universally renowned UTM machine, there is no transition and you will conduct standard tests or more elaborate studies. The UTM is at the centre of professional testing systems and materials testing machines.

Upgrade your lab with a dependable, authentic and easy-to-use UTM machine. Discover why engineers and experts turn to our UTM machines for UTM testing, tensile testing, and material testing machines across sectors.

Affordable Testing Solutions for Routine and Production Testing

Affordable Testing Solutions for Routine and Production Testing

Providing a cost and functionality balance, this universal testing machine offers affordable solutions for routine testing and production testing and is suitable for use by different organizations. We provide top-notch universal testing machines to overcome errors in your laboratories.

Tensile Testing Equipment for Precision and Accuracy

Tensile Testing Equipment for Precision and Accuracy

Tensile testing equipment with high-performance universal testing machines delivers accurate measurements of tensile stress and tensile modulus, which are substantial for obtaining repeatable test outputs required for quality assurance.

Frequently Asked Questions (FAQs)

Frequently Asked Questions (FAQs)

What is a Universal Testing Machine 5KN, and how does it function?

What is a Universal Testing Machine 5KN, and how does it function?

A Universal Testing Machine 5KN is an all-purpose machine used to test materials’ mechanical properties by performing tensile and compression testing. It works by applying controlled forces on an illustration and measuring its reaction, such as distortion and failure, using high-precision sensors and test software.

What are the main uses of a Universal Testing Machine 5KN?

What are the main uses of a Universal Testing Machine 5KN?

Universal testing machine 5KN is applied in wide applications such as aerospace, construction, and biomedical for the measurement of material strength, elasticity, and lifespan. It is also employed for tensile testing, compression testing, and other material tests for quality and reliability, with industry standards.

How precise is a Universal Testing Machine 5Kn in material testing?

How precise is a Universal Testing Machine 5Kn in material testing?

The machine gives high accuracy in material testing, whose errors range from 0.3% to 1%. And in most instances, less than 0.5%. Such precision gives credible data for measuring the tensile strength, tensile stress, and compression force of materials in universal testing machines.

What to look for when making a selection for a Universal Testing Machine 5KN

What to look for when making a selection for a Universal Testing Machine 5KN

Some of the key features include load capacity and measurement precision compatible with different grips and fixtures. They are simple-to-use testing software and are under international materials testing standards. Also, these multifunctional machines test different materials and types of test frameworks in the tensile testing system.

Is it possible to use a Universal Testing Machine 5KN for tensile and compression tests?

Is it possible to use a Universal Testing Machine 5KN for tensile and compression tests?

Yes, the Universal Testing Machine 5KN is efficacious in tensile testing and compression testing. It operates to adjust fixtures and design to adequately test the material’s mechanical properties under multiple loading conditions.

Choose the Universal Testing Machine 5kN for the accuracy and precision to strength testing materials to the highest standards. This universal tensile testing machine can be and will do it for you in various tensile testing machines applications. The universal testing machines from York Testing Solution are built on a foundation of consistency, durability, and performance for all material testing requirements.

Get Started with the Universal Testing Machine 5KN Today!

Get Started with the Universal Testing Machine 5KN Today!

Ready to elevate your materials testing? Get in touch with us today to schedule a demo or for a quote on the Universal Testing Machine 5KN. Experience the accuracy and reliability that our universal testing machines deliver to your tests.

Extensometer

Extensometer

Available in Long extensometer and short extensometer.

Long Extensometer:

Long Extensometer:

The Long Extensometer is vital for assessing the stretchability of materials like rubber, plastic, PE, fabric, and webbing, especially those with elongation exceeding 20%. Typically, the testing specimen takes the form of a dumbbell, with the gauge length adjustable to suit its dimensions. Throughout the testing procedure, the extensometer adeptly detects any elongation automatically.

Specifications

Specifications

| Specifications | Standard | Extended |

| Test Stroke | 700mm | 1100mm |

| Extensometer Class | C2 | |

| Gauge Length | 15-100mm (Customizable) | |

| Operating Force |

0.25N Top of Form Bottom of Form |

|

| Specimen Thickness | 0.10mm (Depending on the chosen jaw face) | |

| Arms Reach | 110mm | |

| Resolution | 0.0125mm | |

| Stroke resolution | 0.0001 mm | |

Short Extensometer:

Short Extensometer:

The Short Extensometer serves to evaluate the stiffness of materials like rigid plastic, metal, and those with an elongation below 50%. Sporting a refined displacement sensor and a sleek, compact design, it boasts a resolution of up to 0.5μm. Tailored specifications are available for instances where gauge length or elongation exceeds standard parameters. During tests with a maximum load under 20kN, the extensometer can remain affixed to the specimen until fracture occurs.

Specifications

Specifications

| Specifications | Short Extensometer |

| Gauge Length | 25mm/50mm |

| Resolution | 0.0005mm |

| Distance Clamp Rod’s Head | 78mm |

| Maximum Stroke |

25mm Top of Form Bottom of Form |

| Weight | 400g |

| Flat Specimen Thickness | 0-22mm |

| Round Specimen Diameter | Φ4.5-Φ21mm |

| Extensometer Class | C1 |

| Features | Using specialized fixtures to enhance clamping |

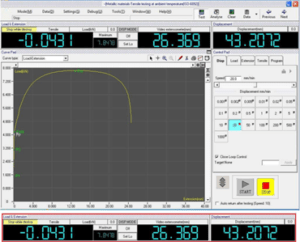

Software Operating Guidelines

Software Operating Guidelines

The YTS software reflects the collective expertise of leading testing machine manufacturers globally, incorporating insights and suggestions from end users. It merges the strengths of previous software versions with numerous new features. Its streamlined structure simplifies testing procedures, making them user-friendly, efficient, and dynamic. Within the main interface, users can access essential functions such as the computer software interface, data display, setup procedures, and sample size adjustment.

| MODEL | YTS-5KN-101 |

| Maximum load | 5kN |

| Calibration criterion | ISO 7500-1 Class 0.5, compliant with ASTM E-4. |

| Testing Load Accuracy | ±0.5% |

| Load Resolution | 1/500000FS |

| Testing Load Range | 0.4%~100%FS |

| Deformation precision | ≤±0.5% |

| Deformation measuring extent | 0.2%~100%FS |

| Deformation resolution | 1/500000FS of the max deformation |

| Test management mode | Three closed-loop controls for stress, strain, and displacement |

| Displacement precision | Within ±0.5% of the value |

| Displacement resolution | 0.04μm |

| Control factors | |

| Constant force control range | 0.001%~5%FS/s |

| Constant force control precision | For rates < 0.05%FS/s, it’s within ±2% of the set value; For rates ≥0.05%FS/s, it’s within ±0.5% of the set value. |

| Constant deformation control range | 0.005~5%FS/s |

| Constant deformation control precision | For rates < 0.05%FS/s, it’s within ±2% of the set value; for rates ≥0.05%FS/s, it’s within ±0.5% |

| Crosshead speed precision | Within ±0.5% of the value |

| Crosshead speed range | 0.001~1000mm/min |

| Mainframe factors | |

| Testing space (Crosshead Travel) | 1100mm |

| Overall Dimensions | 850x550x1824mm |

| Weight | about 420kg |

| Max. Tensile Testing Space | 770mm |

| Test width | 450mm |

| Power supply | 1kW,AC220V±10%,50Hz/60Hz |

| Note: *Extra wide and/or extra height frames are available. *Power supply system is completely customizable. *Tensile space, test width, and speed is completely customizable. | |

Related Products